Cranfield Aerospace Solutions (CAeS) and their technology partner, Reaction Engines, are at the forefront of addressing a critical obstacle in the journey toward hydrogen-electric flight: thermal management. Through their collaboration on Project FRESSON, their innovations mark a significant stride in advancing the feasibility of hydrogen-electric propulsion in aviation.

By retrofitting the conventional Britten-Norman Islander with cutting-edge hydrogen-electric propulsion technology, Project FRESSON’s goal is to pave the way for the world’s first truly green, passenger-carrying airline services from 2027.

Traditional aircraft powertrains typically use hot exhaust gas streams to dissipate most of their waste heat, posing a stark contrast to the thermal management requirements of fuel cell powered aircraft. Hydrogen fuel cells necessitate the rejection of significant amounts of low-grade heat, presenting a unique engineering challenge. Using conventional methods for this heat rejection from hydrogen fuel cells would result in large, heavy heat exchangers, imposing mass and drag penalties that would compromise aircraft range and performance.

CAeS, leveraging its extensive experience in aircraft modification design and certification, recognised the need for collaborative innovation to tackle these challenges effectively. Rather than following a conventional approach of fixed requirements and tendering with suppliers, CAeS embraced an iterative collaboration model with technology partners Reaction Engines. This approach ensured that each component was optimised within the context of the overall system design, fostering a holistic solution to thermal management.

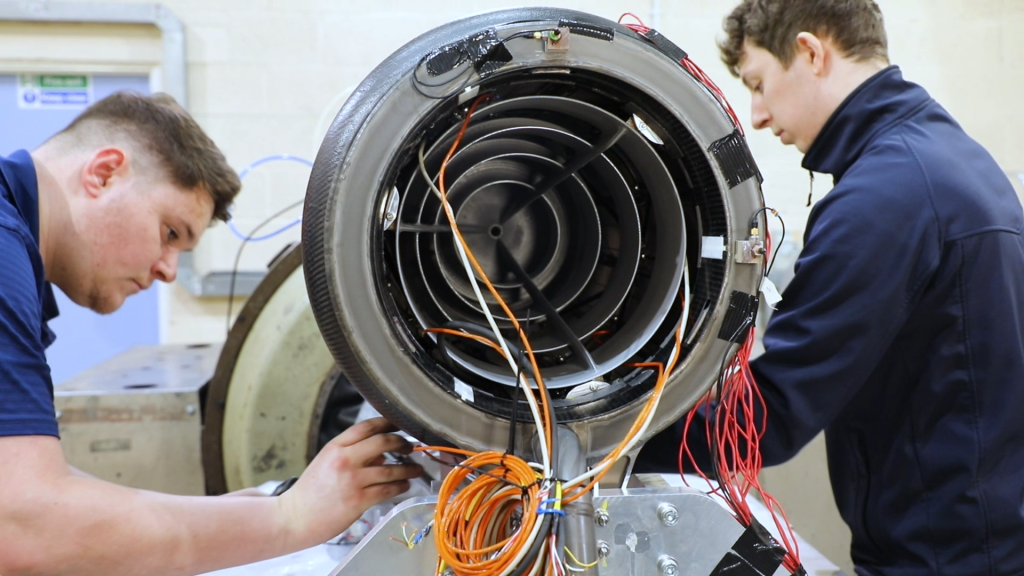

Central to the project’s success is the adoption of annular microtube radiators, game-changing thermal management technology developed by Reaction Engines. These radiators, utilising mixed counter-crossflow to maximise efficiency, represent a shift in heat exchanger architecture. The collaboration has resulted in a lightweight, efficient radiator capable of rejecting over 300 kW of low-grade waste heat while minimising mass and drag penalties.

The project boasts a formidable lineup of partners, including Evolito, renowned for their breakthroughs in electric motor technology, Ricardo, spearheading the development of the hydrogen fuel cell in collaboration with CAeS, and Britten-Norman, the manufacturer of the BN-Islander aircraft serving as the testing platform for this innovative technology integration.

Through a shared vision, multidisciplinary expertise, and a relentless commitment to excellence, Project FRESSON is paving the way for a greener, more sustainable future in aviation.