Cranfield Aerospace Solutions’ Hydrogen Aircraft: Fuel Cell Technology Explained

Hydrogen aircraft are the future of aviation. They can greatly reduce greenhouse gas emissions in comparison to traditional fuels. As the aviation industry moves toward zero emission flights, hydrogen aircraft offer a practical way to reach this goal and help fight climate change.

As someone interested in the future of aviation, you understand the pressing need for sustainable solutions. The shift to zero-emission flight isn’t just a distant goal—it’s an essential change that’s already taking shape. At Cranfield Aerospace Solutions, we’re driving this transformation by developing hydrogen aircraft technology to meet the demands of a decarbonised future.

Key Components of our Hydrogen Aircraft Fuel Cell Technology

Cranfield Aerospace Solutions is pioneering hydrogen aircraft technology. We are transforming a standard Britten-Norman Islander aircraft to use hydrogen propulsion. This project will prove that hydrogen aircraft are a viable, sustainable solution for aviation and help advance the development of commercial, certified hydrogen planes.

We have intricately designed our hydrogen aircraft technology. Here’s how we’re making it work:

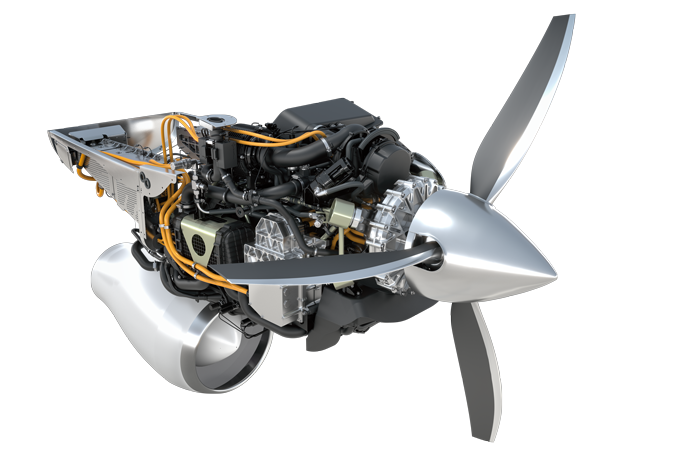

- 250kW Hydrogen Fuel Cell System: Located in each nacelle, it includes fuel cell stacks, balance of plant, and a control unit.

- 220kW Electric Propulsion Units: Each nacelle contains motor and inverter-controllers.

- Propellers: Conventional, 3-blade, variable pitch, max RPM 2300.

- Hydrogen Fuel Distribution System: Ensures efficient fuel delivery from tank to fuel cell.

- Hydrogen Fuel Tanks: 350 bar gaseous tanks for optimal storage.

- Power Distribution System (PDS): Manages electrical power throughout the aircraft.

Advantages of Hydrogen Aircraft: Gaseous vs. Liquid Hydrogen

Hydrogen aircraft can use hydrogen in gaseous or liquid form. Each has distinct advantages and challenges.

Why Gaseous Hydrogen for Aircraft?

Gaseous hydrogen is an ideal entry fuel for smaller hydrogen aircraft, paving the way for zero-emission aviation.

- Handling and Storage: Gaseous hydrogen is easier to manage than liquid hydrogen. It doesn’t need extreme storage conditions and is simpler to handle when it comes to venting and pressure management.

- Transportation: Gaseous hydrogen is easier to transport and is already used in many industries.

- Cost-Effectiveness: Gaseous hydrogen could be cheaper than traditional kerosene. Advances in hydrogen production, storage, and fuel cell technology are expected to reduce costs over time.

- Infrastructure: We can use existing knowledge from other industries to help build the infrastructure needed for hydrogen aviation.

By starting with small hydrogen aircraft, the industry can accelerate the development of regulations, airport operations, and maintenance protocols.

Liquid Hydrogen for Aircraft

As we look to the future, liquid hydrogen presents opportunities for long-haul flights and larger aircraft.

- Storage Efficiency: Liquid hydrogen doesn’t require heavy pressurised tanks but needs highly insulated tanks due to storage at -253°C.

- Extended Range: Storing more fuel enables longer flights, making liquid hydrogen crucial for fully decarbonising aviation.

Challenges in Hydrogen Aircraft Development

Developing hydrogen aircraft isn’t without its challenges. At Cranfield Aerospace Solutions, we’ve identified and addressed several key areas:

- Packaging the Hydrogen Fuel Cell Technology: Fitting a hydrogen fuel cell system into an aircraft’s nacelle is challenging because of space and safety. We’ve designed a solution that meets these strict requirements.

- Thermal Management: Hydrogen fuel cells produce low-grade heat, therefore they need different handling compared to traditional engines. We’ve tackled this challenge using advanced thermal management solutions from Reaction Engines.

- Standards and Regulations: The rules for hydrogen technology are still being developed, therefore is is key that we’re working closely with authorities like the CAA to create standards that ensure hydrogen systems can be safely and effectively used in aviation.

- More power: The packaged solution will produce 110% of the power of the engine it is replacing

- Heat removal: The thermal management solution is sized to remove 100% of the waste heat from the system

- Safe solutions: All zones within the nacelle and the entire aircraft have been classified for hydrogen and electrical equipment presence. Safe solutions for detecting hydrogen leakage and ensuring proper ventilation have been implemented

The Future of Hydrogen Aircraft Design

Hydrogen technology isn’t just changing how aircraft are powered, it’s also influencing their design. Traditional aircraft designs were built around kerosene-based fuels, but hydrogen requires a new approach. By designing aircraft around hydrogen fuel systems from the outset, we can optimise for efficiency, reduce nacelle sizes, and explore innovative power distribution configurations.

[Editors note: This post was originally posted on the 23rd August 2023 and has been updated for freshness and accuracy]